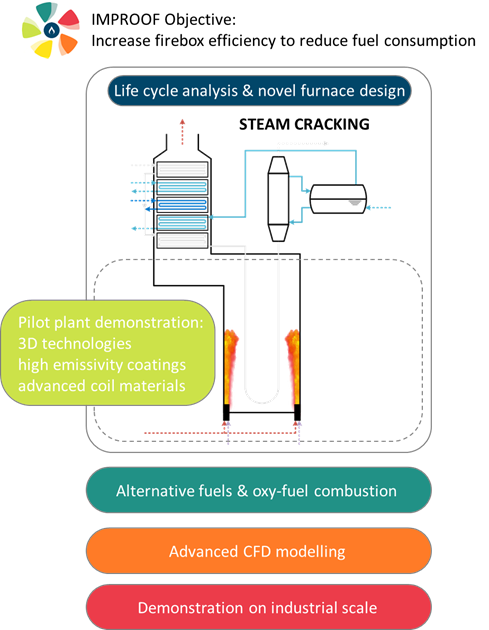

IMPROOF is a European project aiming at improving the energy efficiency of steam cracking furnaces by at least 20%, while reducing emissions of greenhouse gases and NOx by at least 25%.

The strongly industrial oriented consortium is composed of 7 industrial partners, including 2 SME completed by 2 RTO and 2 Universities, showing a clear and strong path to the industrial and economical world.

Start date: 1 September, 2016

End date: 30 November, 2020

Grant number 723661

CONTACT

Kevin.VanGeem@UGent.be