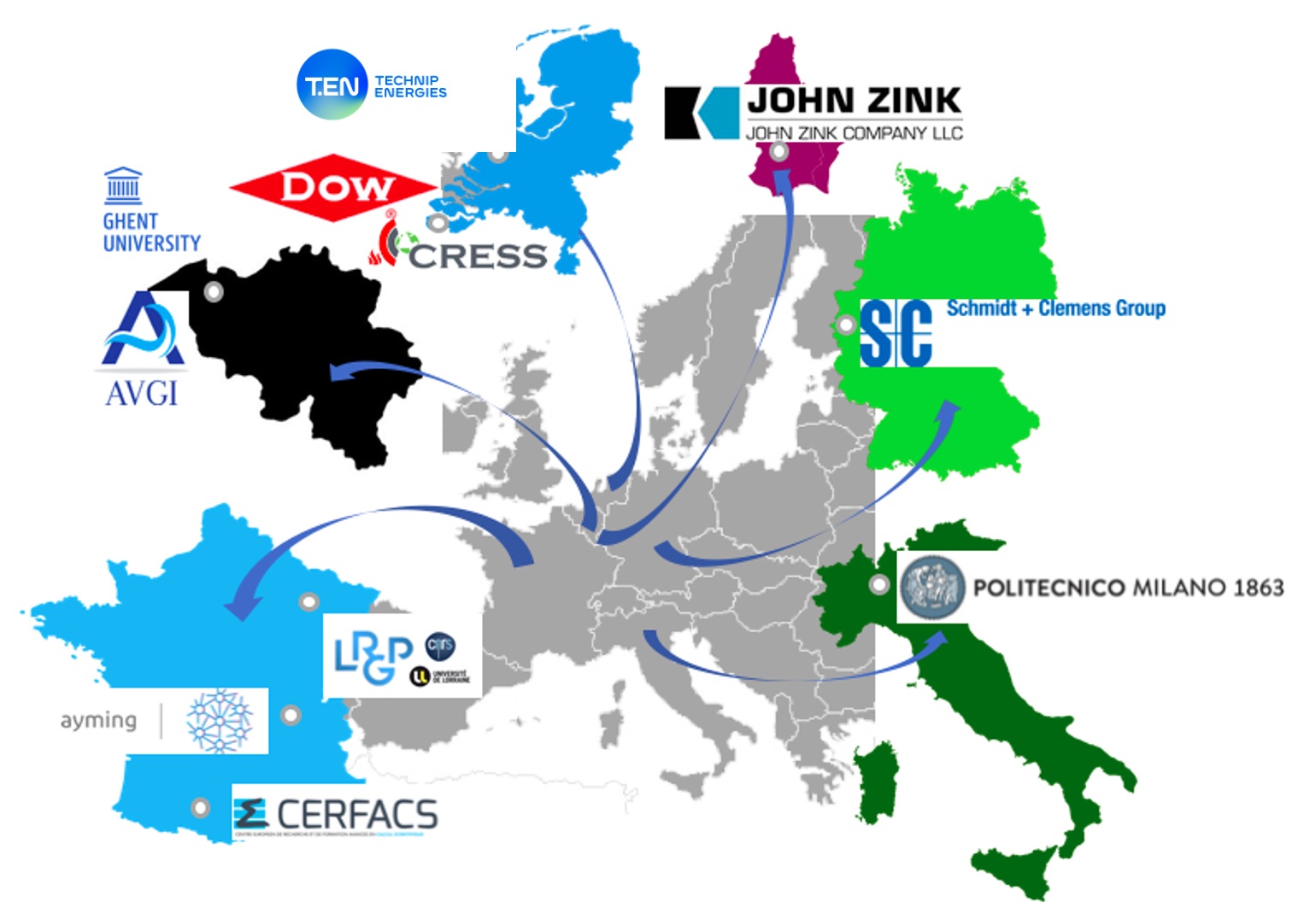

- Project coordinator

Ghent University coordinates the project and leads the development and integration of furnace system innovations through pilot plant testing and advanced process simulation (kinetic modeling and CFD modeling). Furthermore, Ghent University will be involved in the scaling up study as well as in the sustainability assessment of the new technology.

Ghent University coordinates the project and leads the development and integration of furnace system innovations through pilot plant testing and advanced process simulation (kinetic modeling and CFD modeling). Furthermore, Ghent University will be involved in the scaling up study as well as in the sustainability assessment of the new technology.

Dr. Prof. Kevin Van Geem is the project coordinator

Contact:

| kevin.vangeem@ugent.be | marko.djokic@ugent.be | www.lct.ugent.be |

- Partners

|

AVGI will give a qualitative and quantitative evaluation of the techno-economic, environmental and operational advantages of developments made in IMPROOF. The involved people are Ismaël Amghizar and David J Brown. |

| Contact: | |||

| ismael.amghizar@avgi.be | david.brown@avgi.be | guy.marin@telenet.be | www.avgi.be |

|

Ayming, with UGENT, helps the partners to focus on their R&D activity by following up the project (strategic, admin and financial). Ayming also participates in the dissemination of the results through the stakeholders management and networking. On the project outcome valorization activities, Ayming focuses on the exploitation and commercialization of the project results. Pre-business plan, key technology identification as well as ecosystem analysis and benchmark are proposed to clearly design the quickest route to the market. On this aspect, intellectual property will also be managed by Ayming to assure IP capture and ultimately propose a complete freedom to operate to the whole consortium. |

Contact:

plenain@ayming.com www.ayming.com

CERFACS is a leader of CFD applied to turbulent reacting flows and performs simulations of furnaces and reactors to understand the physics and evaluate the impact of new technologies. The involved people are Dr. Bénédicte Cuenot and Dr. Eleonore Riber.

Contact:

| benedicte.cuenot@cerfacs.fr | eleonore.riber@cerfacs.fr | www.cerfacs.fr |

LRGP-CNRS will produce reliable experimental data on the combustion of biogas and bio-oil surrogates.

Dr. Frédérique Battin-Leclerc, expert in detailed gas-phase kinetics, will be in charge with Dr. Olivier Herbinet and Hervé Le Gall.

Contact:

| frederique.battin-leclerc@univ-lorraine.fr | olivier.herbinet@univ-lorraine.fr | rgp-nancy.cnrs.fr |

The involved people are Joost Van Thielen and Linda Keijmel .

Contact:

joost.vanThielen@cressbv.nl www.cressbv.nl

DOW will contribute to the upscale of the technology at commercial level.

Dr. Georgios Bellos will monitor trials and perform a statistical and modelling evaluation of the new technology in the field.

Contact:

bellos@dow.com www.dow.com

John Zink will provide demonstration testing of the combustion equipment in a test furnace that is representative of a steam cracker.

People involved are Gilles Theis, Ali Gueniche Hadj and Mike Henneke.

Contact:

| hadj-ali.gueniche@johnzink.com | Gilles.Theis@johnzink.com | www.johnzink.com |

POLIMI's main role is the development of detailed kinetic mechanisms to model the combustion of the different fuels that will be adopted in the project.

The involved people are Prof. Tiziano Faravelli, Prof. Alberto Cuoci and Prof. Alessio Frassoldati.

Contact:

| tiziano.faravelli@polimi.it | alessio.frassoldati@polimi.it | www.polimi.it |

| The role of S+C in the project is to propose the ideal alloy for tubes and fittings for the radiant zone in relation with the changes in the process circumstances in the oxyfuel fired and emissivity coated furnaces.

Cor Visser, Dr. Jakobi Dietlinde, Dr. Jorg Weigandt and Sebastian Klein participate to the project. |

Contact:

| d.jakobi@schmidt-clemens.de | j.weigandt@schmidt-clemens.de | www.schmidt-clemens.com |

|

Technip Energies’ main involvement is in the modelling of the cracking furnaces using their proprietary cracking furnace simulation program SPYRO® Suite 7, both for the demonstration furnace and for the future furnace including all the modifications required to achieve the targeted reduction of CO2 and NOx emission. In addition, Technip Energies will be performing the engineering of the new radiant coils for the demonstration furnace, based on advanced 3D technologies. Furthermore, Technip Energies is supporting the testing of the 3D reactor, CFD modelling of the cracking furnaces and will aid in the analysis of the pilot plant results. People involved are Dr. Marco Van Goethem and Peter Oud . |

Contact:

| peter.oud@technipenergies.com | marco.van.goethem@technipenergies.com | www.technip.com |

- Associate Partner

| Emisshield will provide High Emissivity materials for refractory, ceramic fiber and metals along with assistant on spectral and hemispherical emissivity test procedures for the IMPROOF project. Dr. John Olver and Dr. John Dillard will monitor the development and use of High Emissivity Materials and assist with the evaluation of such Materials in pilot scale and full plant implementation studies. |

Contact:

John.Olver@emisshield.com www.emisshield.com